Let’s face it, everyday in an In-Plant is about survival of outsourcing, budget cuts, employee retention or any combination of a dozen other threats. So, when I heard rumors that the In-Plant that I was just hired at might be closing, my first goal was to transform it into one of the most efficient, leanest running and highly valued departments in the system. Every day since, I’ve continued a constant search for winning ideas to accomplish exactly that, and after twelve years, here are my top 6 Winning Ideas for In-Plant Survival:

1. Updating equipment and attitudes

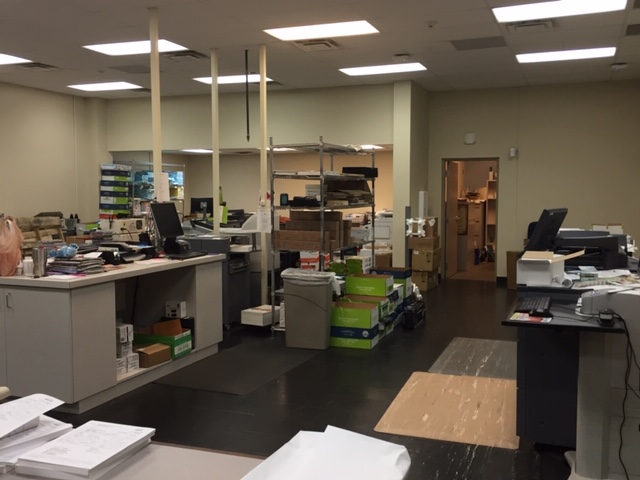

We replaced outdated digital equipment with a mix of offset and digital which enabled us to run more cost efficiently by routing short runs to our Konica 6501 and long runs to our Presstek 34DI. Another major effort as manager was to change the atmosphere of the shop from an attitude of the customer gets what we give them, to a customer service approach of the customer is always right. We constantly communicate with our customers about what stocks, designs, finishing services, etc., that will help them achieve their goals and proactively share new products and approaches to help them envision new ways that our department can help them.

2. Improving processes and fulfillment

We created warehouse stock items for jobs that were being ordered by multiple departments (10 or more) and reoccurring monthly orders that were being used by a few departments, thus allowing us to run larger orders with a savings of man hours, material costs and giving us more control over our press schedule.

3. Cultivating relationships and allies

We work hard to be a valuable partner to our departments and have built close relationships by rushing last minute work, special ordering stocks, finding vendors for work we can’t do in house and simply being a resource for the best ways to accomplish their goals. I make it a point to have a personal contact within departments and become an ally and friend that knows their family and what’s going on in their lives, and what will make their work life easier, so they can get home to their families. This investment pays off in so many ways. The trust we have earned helps when we have technical issues or shifting priorities that delay or change what we can deliver. Our partners know our commitment and adapt much easier because of this.

4. Generating employee culture and satisfaction

In our department, and in our system, we prioritize a healthy and fun environment. We connect as a team and with other teams by having weekly lunches and snack days, walking to get exercise on our breaks, and having bar-b-ques and birthday celebrations with the other departments in our building. We try to keep the mood light by playing radio stations or cd’s while we work, and we have a nerf gun and other toys for particularly stressful days. We enjoy the benefits and celebrations that our system offers, including continuing education, employee bonuses, an annual employee picnic, food truck visits from The Varsity, employee carnivals, ice cream socials, Easter egg hunts, movie nights with the family, drawings for gifts, etc.

5. Researching products and stocks

“You can do that?” This is something I often hear because I constantly research, test and share new products or stocks that will allow us to offer valuable products in a more cost-effective way. For example, we now offer a repositionable cling fabric that is easy to apply and move repeatedly, which is a big deal when you have wide ranging construction taking place across all five campuses. Also, we are now offering several polyester products such as our nurses’ badges that will run through our Konica Minolta presses, that are pre-perforated, tear proof and can be wiped down with alcohol to be sterilized. We love it when our departments are inspired to come up with a creative use for a new product we’ve shown them.

6. Automating equipment and software

Some of our most valuable automation improvements have been purchasing Print Shop Pro web to print software to streamline our ordering process, save valuable man hours by cutting the number of touches, phone calls, inventory management, etc. Also, adding a Duplo 616 Pro to make finishing more hands off on business / appointment cards, direct mailers, rack cards, notification cards, etc.

It may be hard to believe, but through these and other improvements, we have managed to remain a two-employee department efficiently fulfilling the needs of our health system that has seen a growth of 68%. I encourage you to walk in to work every day the same way I do, with that goal in mind of being one of the most efficient, leanest running and highly valued departments for your company.

Gayle Robinson, C.G.C.M., F.C.P. is Print Shop Production Manager for Tanner Health System, a nonprofit regional health system serving a nine-county area of west Georgia and east Alabama. She has been the Print Shop Production Manager for Tanner Health System for 12 years. Robinson has a background in graphic design, printing and photography with a bachelor’s in mass communications from University of West Georgia. She manages the day-to-day operations for the health system’s in-plant and operates equipment on the shop floor. The in-plant operation serves Tanner’s five regional hospitals, 30 health system-owned physician practices and more than 3,000 employees.

Robinson is a Fiery Certified Professional (FCP), a Certified Graphics Communications Manager (CGCM) and has been an IPMA member since 2013.