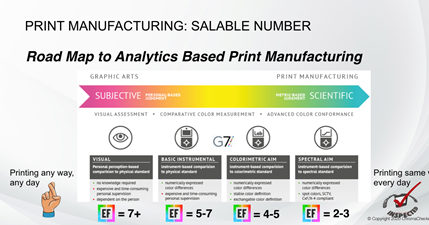

The printing industry has been attempting to make the transition from graphic arts industry (where color is visual and subjective to every participant) to manufacturing industry for 20+ years with very little success. Most printers still rely on people’s eyes and subjective assessments to “get by.” But with 75% of the printers now making less than 2% on margin* (pre Covid19); it becomes imperative that printers decrease waste and improve profitability meaning- transition to a manufacturing mindset if they hope to prevail in the long term.

How does a printer start to make this transition?

Let’s look at this definition of “Manufacturing” – company that takes raw material (ink and paper) and creates a product (printed work) that meets customer expectations (salable). Every printer creates products, but how many assess the salability of the resultant product? Very few do. How does the printer quantify and assess if the result is salable?

How do we do it today?

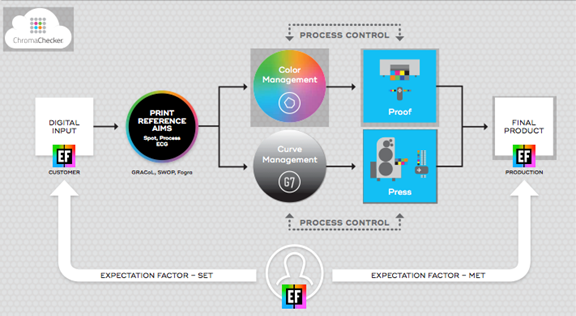

Our industry has done very little to quantify what is acceptable color because tools and technology were not available until recently. In the past printers have attempted to get G7 Qualification, or tout the ability to match their proof, or prove that they can get an 85 score or be ISO qualified, but none of these quantify if the color will meet the customer’s expectations of a color match. Why? Because customers have different expectations for color matches, and few have been trained on what is realistic. Especially with new print buyers in the industry, these people have to rely on their subjectivity to determine what is “close enough.” I have encountered many situations where I have been told that G7 doesn’t work because the two sheets don’t match each other, even if they are both G7 Color Space compliant (the tightest assessment available). The reason is, that G7 is a methodology that provides a shared visual appearance between any CMYK device on any substrate. Nowhere will you find any material from Idealliance (owners of G7 methodology) that states it provides a color match, because it can’t. G7’s methodology is based on gray balance and tonality, not color! For true color match, you need to implement ICC color management software, and to assess the accuracy of a color match, you need to use the E-Factor metric.

How to define salability.

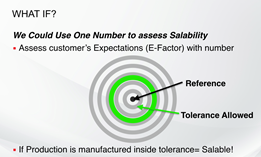

The industry has a metric that quantifies color match that has been researched and sporadically implemented for 20 years called the CRF at 95th percentile delta E (00)- we coined the word E-Factor to simplify this technical term. “E”-Factor has dual meaning, first it is based on a type of delta E, and second it can quantify customer Expectations. This metric has proven to be a reliable predictor of specific customer expectations, and when the printing device can meet or exceed those expectations ahead of time.

The industry has also defined reference print conditions for printing on different substrates, for instance, printing on coated gloss paper is usually referenced to GRACoL print conditions, standard printing on a #1 or #2 paper. Think of it as a bulls eye for optimum accurate printing. E-Factor represents how many rings the print is off of the reference condition (GRACoL).

Where does process control fit relative to salability?

Process control has been widely taught as a key component to help make a printer profitable, but how much and what type of process control is required? It depends on the customer expectations. The more demanding the customer expectations the more process control is required. Process control ensures a process is predictable, stable and operates within a target level of performance… but what is that? It depends on customer expectations. Only when we have established customer expectations, can we implement process control tools and procedures to our manufacturing process to ensure the target level of performance meets customer expectations.

Real life example:

A simple example can be applied to an HP Indigo digital printing press, one of the top quality digital presses available. When installed, it is often configured to match the Indigo standard, which creates nice looking prints, but is 7 E-Factor different to GRACoL. By applying G7 Curves to the print configuration (5 minutes work) the printer can be brought to a 5 E-Factor to GRACoL. And by creating and applying an ICC Profile (20 minutes) the device can be within a 3 E-Factor to GRACoL. More effort, but more accurate result.

What are customer expectations for Print?

Our research (multiple projects) shows that if the match is less than 3 E-Factor, virtually all buyers will accept the print and if over 8 E-Factor virtually all will not accept. 4-7 E-Factor is the danger zone where you are leaving the subjectivity to the pickiness of the buyer, and most printing devices print in this zone leaving the printer very vulnerable to customer refusal to pay.

Make the transition to Print Manufacturing

Use intelligent software to measure the results out of every one of your printing devices and quantify the E-Factor. Prioritize effort to fix the printers with the highest E-Factor first, and work your way to the your most reliable printing devices. Make it a habit, force the operators to check the printers at least once a day, for offset, ideally every job. Start rewarding operators that are maintaining their devices into a salable E-Factor because they are making your company money. If your organization is in the 75% of printers making less than 2% margin on sales, a simple $200 of reduced waste results in a new customer worth $10,000 in new sales. (200/.2). This is significant, and most managers don’t understand this relationship of waste to profitability. This can greatly improve your profitability overnight. Start today, free trial software available to assess the E-Factor for all your print devices, and light booths: https://chromachecker.com/trial. Click here to determine visual expectation (E-Factor) of your desired color matches:https://chromachecker.com/cee/en/manual.

This is all available to take advantage of to improve the profitability of your company and get you on the track to becoming a Print Manufacturer. Look for software that will assess, track and often correct for every variable related to your print manufacturing process including the print, plate, instrument, lighting and more.

David Hunter is co-founder and principal at ChromaChecker. He is an accomplished and recognized expert in color control and management with a proven 30+ year career commitment to the Graphic Arts Industry.

In 1998 he was one of Apple Computers first three ColorSync Profilers. In 1999 he co- founded the PIA Color Conference with PIA, is one of the first G7 Experts, and one of six G7 Expert trainers in the world. David has co-authored several TAGA papers related to Color Matching and Common Color Appearance, researching how buyers judge color. He currently one of five North American members of the international CIE Committee (TC 8-16) studying how humans perceive common color appearance.

David has pioneered a process that quantifies a person’s expectation of color match acceptance (E-Factor) and carries it through the complete manufacturing workflow, ensuring success for manufacturers and their customers.

He can be contacted 651.717.0590 or david@chromachecker.com